Picture this: A 7.8-magnitude earthquake strikes without warning. Buildings sway like reeds in the wind, concrete cracks like eggshells, and entire city blocks transform into rubble. Now imagine your business—your life’s work—buried under that debris. For starter entrepreneurs building offices, factories, or retail spaces in earthquake-prone regions, structural safety isn’t just engineering jargon—it’s existential. Let’s dive into the science, strategies, and seismic innovations that could save your venture from becoming a statistic.

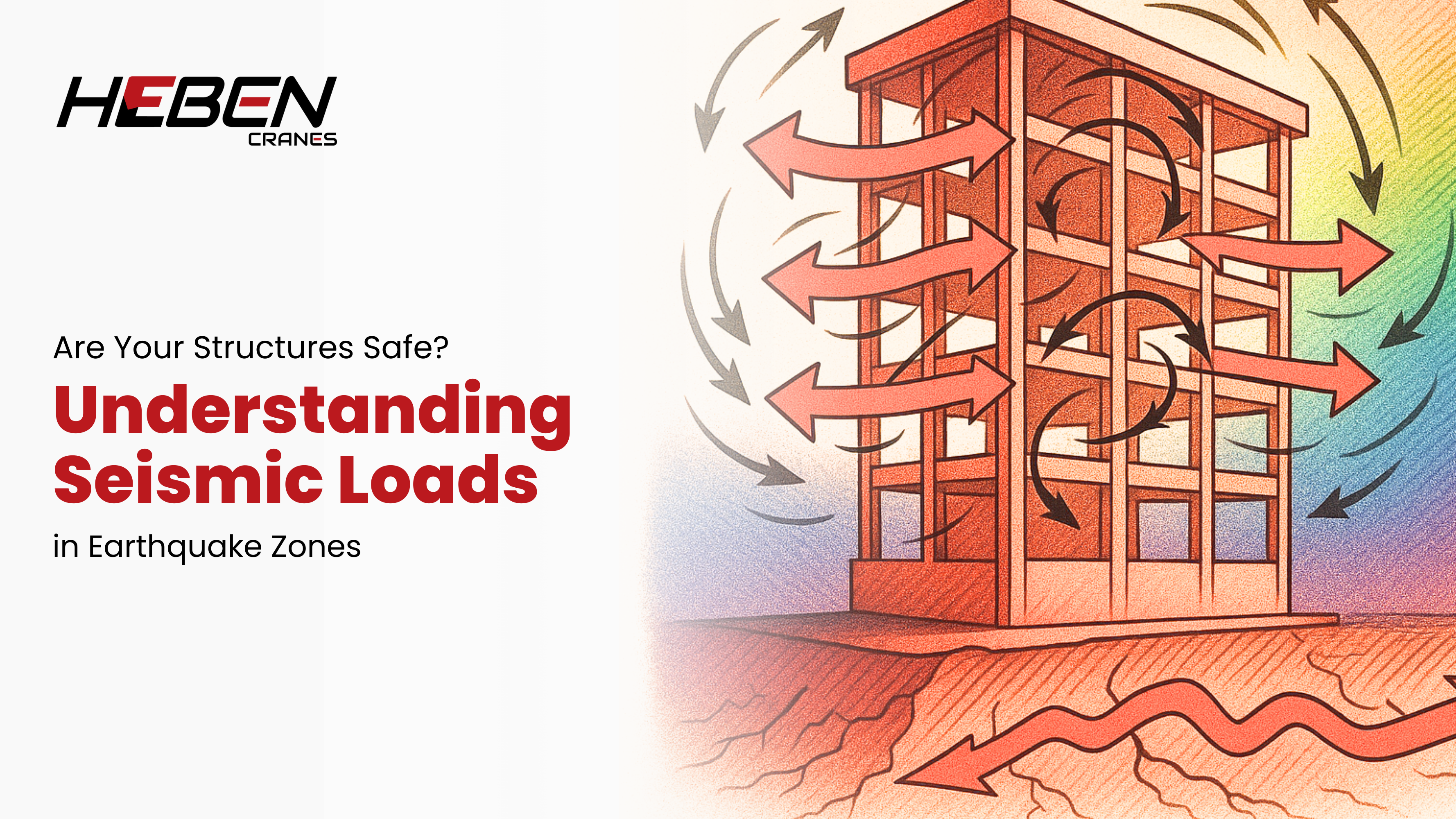

The Hidden Physics of Earthquakes: Why Your Building Isn’t Just Shaking—It’s Dancing

Earthquakes don’t just “shake” buildings. They send shockwaves through the ground at speeds up to 14,000 km/h, triggering complex vibrational patterns. Imagine your structure as a tuning fork: If its natural frequency matches the earthquake’s vibrations, resonance amplifies the motion exponentially. This is why Mexico City’s 1985 quake toppled 400 mid-rise buildings (6-15 stories) while sparing shorter and taller structures—their frequencies didn’t sync with the quake’s 2-second wave period.

Modern seismic analysis uses tools like modal response spectrum analysis to predict these interactions. As Ben Moerman, a seismic engineer specializing in mass timber, explains: “We’re not just building stronger—we’re building smarter. By modeling how different materials and shapes respond to ground motion, we can design structures that literally dance around disaster.”

The Three Killers: Shear, Torsion, and Liquefaction

- Shear Failure

Horizontal seismic forces can slice buildings diagonally like a knife through cake. The 1995 Kobe earthquake demonstrated this brutally: 150,000 buildings collapsed when unreinforced masonry walls sheared apart. - Torsional Twist

Irregularly shaped buildings spin during quakes. The 2010 Chile earthquake saw a 21-story tower rotate 15 degrees on its base—its asymmetric design created lethal torque. - Liquefaction

Saturated soils turn to quicksand, swallowing foundations whole. In Christchurch’s 2011 quake, entire neighborhoods sank 1 meter as the ground liquefied.

Earthquake-Resistant Design: Where Physics Meets Art

The Ductility Paradox: Strong vs. Flexible

Conventional wisdom says “build stronger.” Seismic engineers say “build flexible.” Ductile materials like steel-reinforced concrete and cross-laminated timber (CLT) absorb energy through controlled deformation. A study from the University of Ljubljana found that ductile buildings sustain 40% less damage than rigid ones during moderate quakes.

Key design strategies:

- Base Isolation Systems: Floating buildings on lead-rubber bearings or sliding pads reduces ground motion transfer by 80%.

- Energy Dissipaters: Hydraulic dampers act like seismic shock absorbers, converting destructive energy into heat.

- Strong-Column Weak-Beam: Ensures beams fail before columns—a sacrificial design that prevents total collapse.

The Mass Timber Revolution

While steel and concrete dominate skylines, engineered wood is rewriting the rules. Mass timber’s natural flexibility and lighter weight make it ideal for seismic zones. Vancouver’s groundbreaking 14-story Brock Commons Tower—the world’s tallest timber building in an earthquake zone—uses steel-reinforced CLT shear walls that flex without fracturing.

“Timber’s vibration damping is 300% better than concrete,” notes Moerman. “Plus, it’s sustainable—every cubic meter sequesters a ton of CO₂.”

Actionable Insights: Protecting Your Business

1. Demand a Site-Specific Seismic Hazard Analysis

Ground motion varies wildly within small areas. The 1994 Northridge quake showed peak accelerations of 1.8g in some neighborhoods—nearly double nearby areas.

2. Insist on Performance-Based Design

Forget prescriptive codes. Modern approaches simulate your exact building through nonlinear time-history analysis, testing against 100+ historical quakes.

3. Protect Non-Structural Elements

In the 2019 Ridgecrest quakes, 70% of business losses came from toppled shelves and shattered pipes—not structural damage. Use braced shelves and flexible utility connections.

4. Plan for the Aftermath

The 2023 Türkiye quakes proved backup systems matter: Businesses with seismic gas shutoffs had 89% faster recovery times.

The Future Is Resilient (and Profitable)

Seismic safety isn’t just about survival—it’s smart economics. Japan’s Earthquake Business Continuity Plan certification increases property values by 15%. Insurers offer 30% premium discounts for dampers and base isolation.

As you build your empire, remember: In earthquake zones, the ground might be unstable, but your business doesn’t have to be. By marrying cutting-edge engineering with entrepreneurial vision, you’re not just constructing buildings—you’re forging legacies that will outlast the tremors of time.